Machine Vision

Continuous monitoring is enabled by using machine vision to empower computers with the ability to visually interpret and process images.

Why Machine Vision?

Machine vision, also known as industrial computer vision, is a technology that enables machines to see, interpret and understand visual information in a way similar to the human eye and brain. By utilizing cameras and image processing algorithms, machine vision systems can analyze and extract data from images to make informed decisions or perform specific tasks. From quality control and robotic guidance to facial recognition and autonomous vehicles, machine vision plays a crucial role in enhancing efficiency, accuracy and automation across different sectors.

Machine vision technology can be utilized across various industries and sectors to streamline processes, enhance quality control and improve operational efficiency. Some common applications of machine vision include:

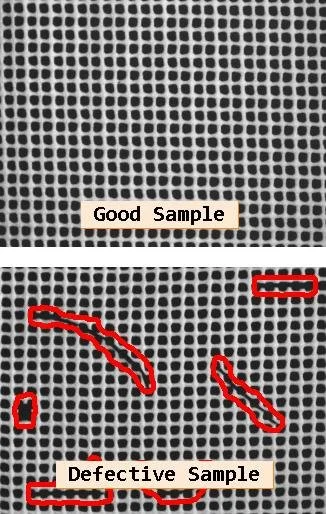

Manufacturing: Machine vision is widely used in manufacturing to automate inspection tasks, identify defects in products, guide robots on the assembly line and ensure products meet quality standards.

Automotive: In the automotive industry, machine vision is implemented for parts inspection, barcode reading, robot guidance and quality control during the manufacturing process.

Healthcare: Machine vision systems play a crucial role in medical imaging, diagnosis, surgery and detecting anomalies in scans like X-rays and MRIs.

Retail: Retailers utilize machine vision for various applications such as inventory management, self-checkout systems, monitoring foot traffic in stores and analyzing customer behavior.

Security: Machine vision is employed in surveillance systems for facial recognition, intruder detection, monitoring crowded areas and identifying suspicious behaviors.

Agriculture: In agriculture, machine vision technology helps in crop monitoring, sorting fruits and vegetables, detecting plant diseases and optimizing harvesting processes.

Pharmaceuticals: Machine vision assists pharmaceutical companies in packaging inspection, product labeling verification and ensuring compliance with regulatory standards.

These are just a few examples of where machine vision can be applied. The flexibility and accuracy of machine vision technology makes it a valuable tool in various industries, paving the way for improved efficiency and productivity.